China High Quality Injection Mold Engineering Manufacturers – UPVC fitting mould Steel of Cavity & Core DIN 1.2316 – Yaxi Mould

China High Quality Injection Mold Engineering Manufacturers – UPVC fitting mould Steel of Cavity & Core DIN 1.2316 – Yaxi Mould Detail:

v:* {behavior:url(#default#VML);}

o:* {behavior:url(#default#VML);}

x:* {behavior:url(#default#VML);}

.shape {behavior:url(#default#VML);}

| Model NO. | JZ-P-C-03-021-A | Warranty | 12 Months |

| Metal Color | Black Metal | Customized | Customized |

| Condition | New | Size | 100mm |

| Transport Package | Wooden Case | Specification | IS09001: 2000 |

| Trademark | JZ | Origin | China |

| HS Code | 8480719090 | Production Capacity | 100 Sets/Month |

Product Description

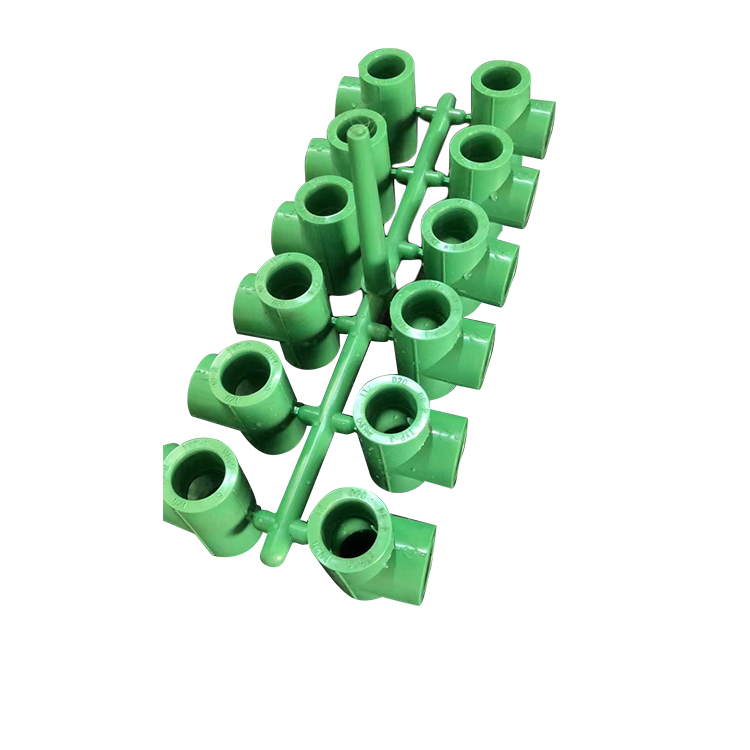

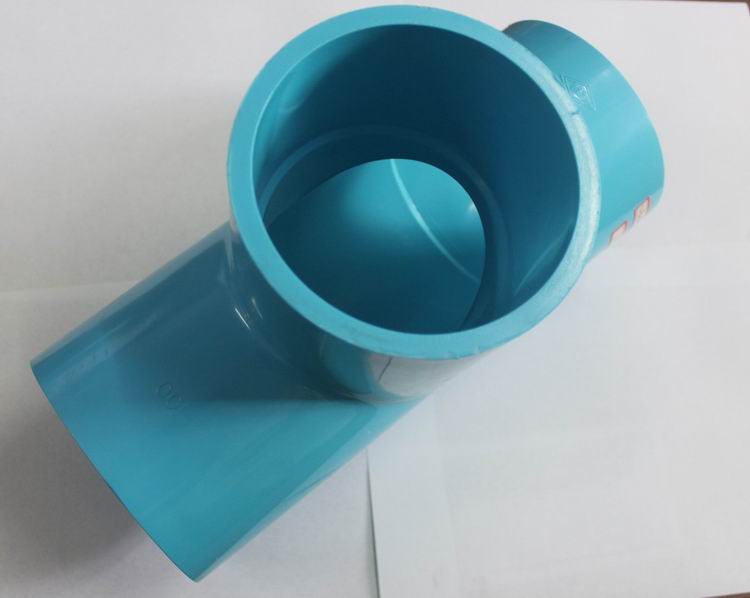

PVC Injection Collapsible Core Fitting Mould

High quality with reasonable price and short delivery time

| Name | PVC Injection Collapsible Core Fitting Mould |

| Plastic material | PVC |

| Steel of Cavity & Core | DIN 1.2316 |

| Steel of Mouldbase | S50C. LkM standard^ etc |

| Nos of Cavity | Customized |

| Hardness of Cavity & Core | 42-45HRC |

| Hardness of Wear Parts | 42-48HRC |

| Core pulling system | Motor /oil cylinder/ stripping plate, angel pin^ etc |

| Mould Accessories | DME/HASCO Standard A |

| Cooling system | In core baffle cooling and in cavity plate chain dilling type cooling |

| Surface fnish | Diamond polish |

| Molding life | 1,000, 000shots |

| Runner | Cold |

| Delivery time | 75 work days |

| Packing | wooden case |

| Payment | T/T L/C |

Serve

1. R& D We support customer R& D.

2. Quotation Making Mould Quotation will be finished in one day based on information given.

3. Negotiation The quality, price, material, delivery time, payment ect.

4. Mould Design 3-5 days for mould and product 3D drawing design

5. Mould Make moulds based on customers’ requirements. Mould design sent to customer for approval first.

Mould will be usually finished in 60 days

6. Mould Testing When moulds are finished, we will test the mould to check whether it meets customers’ needs.

And we will send samples for reference.

7. Sample If the first sample comes out do not satisfy customers, we will modify the mould until meeting

customers’ satisfaction.

8. Delivery Deliver by sea or by train for PPR pipe mould, according to customers’ requirement.

Product detail pictures:

Related Product Guide:

Cooperation

We believe in: Innovation is our soul and spirit. Quality is our life. Customer need is our God for China High Quality Injection Mold Engineering Manufacturers – UPVC fitting mould Steel of Cavity & Core DIN 1.2316 – Yaxi Mould , The product will supply to all over the world, such as: Malta, Madagascar, Czech republic, We guarantee that our company will try our best to reduce customer purchase cost , shorten the period of purchase , stable merchandise quality , increase customers' satisfaction and achieve win-win situation .

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.