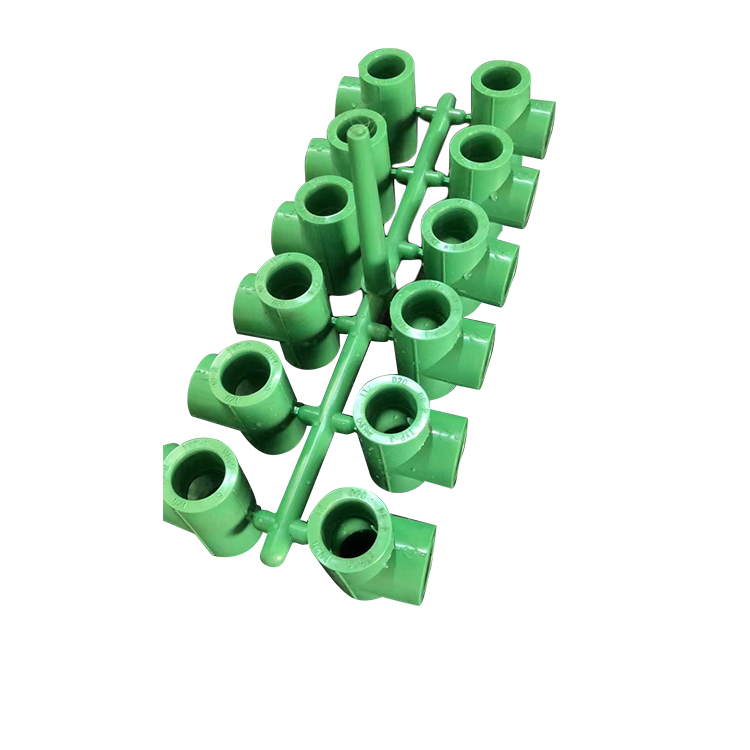

China High Quality Reverse Injection Molding Factory – Ppr fitting mould nos of cavity customized – Yaxi Mould

China High Quality Reverse Injection Molding Factory – Ppr fitting mould nos of cavity customized – Yaxi Mould Detail:

v:* {behavior:url(#default#VML);}

o:* {behavior:url(#default#VML);}

x:* {behavior:url(#default#VML);}

.shape {behavior:url(#default#VML);}

Product information

| 1.Product name | Customized electronic hardware plug shrapnel stamping parts copper sheet battery socket AA shrapnel |

| 2.Material | 1.Steel:303/304/316/412/etc 2.Aluminum alloy:5052/6063/2017/7075/etc 3.Brass alloy:3602/2604/H59/H62/etc 4.Steel alloy:carbon steel/ die steel/etc 5.Other special materials :copper /bronze/iron/etc We handle many other type of materials . please contact us if your required materials are not listed material |

| 3.Process | Wire- cutting,EDM,griding, stamping,In-mold injection,CNC etc. |

| 4.Surface treatment | Anodizing/Polishing/(Zinc,nickel,chrome,tin,brass,glod.silver,titanium) Plating /Black Oxide /Hot-dip galvanizing/painting/powdering/electroplating.etc |

| 5.Standard | API.BS.DIN.JIS.GB.etc |

| 6.Shipping | DHL,EMS.UPS or Fedex (fast and safer) |

| 7.Delivery time | Sample: within 7 days. Production: within 15-25 days |

| 8.Size | Depend on the drawing |

Our advantages

1. Brand raw materials, seiko products, quality assurance

2. The core team has more than 20 years of customization experience, which can meet different customization needs of customers

3. Independent mold development and production, automatic production, stamping, injection molding, assembly and other one-stop services

Stamping is the power of conventional or special stamping equipment, so that the sheet metal in the mold directly by the deformation force and deformation, so as to obtain a certain shape, size and performance of the product parts, stamping parts have their own advantages, so its role is very extensive. Aviation, military, machinery, agricultural machinery, electronics, information, railway, post and telecommunications,transportation, chemical, medical appliances, household appliances and light industry and other departments have stamping processing. Airplanes, trains, automobiles,tractors have many large and small stamping parts. Car body, frame and rim and other parts are stamped out. There are food metal can shell, steel boiler, enamel basin bowl and stainless steel tableware, all are stamping products using molds, and even the hardware of the computer is also short of stamping parts.

FAQ

Q:Do you provide free sample?

A:Yes, we provide ready to ship sample for free, but please pay for the freight.

Q:What’s the LEAD time after the order placed?

A.:lt depends on the order quantity. when we have stocks, we can ship it in 2-3days.

Q:How much time to customize a new sample?

A:Usually it will take 3- 10 days to make new samples.

Q: Are you a factory or trading company?

A: we are a factory specialized in hardware hose and electronic products from 2006.

Q: Do you provide OEM service?

A:OEM& ODM is available, we can do OEM with logo, packaging, color, and ect..

Q: How can | pay for my orders?

CUSTOMIZATION SERVICE

1.Delivery time 5-20days for all order

2. Payment Pay 100% of the amount through T/T, paypal, etc

3.Package Custom solution knocked down packing for different design

Q: How to proceed an order ?

A: Firstly, let us know your requirements or application.

Secondly, we quote according to your requirements or our suggestions.Thirdly, customer confirms the samples and places deposit for formal order Fourthly, we arrange the production.

Product detail pictures:

Related Product Guide:

Cooperation

Our goal is to provide high quality products at competitive prices, and top-notch service to customers around the world. We are ISO9001, CE, and GS certified and strictly adhere to their quality specifications for China High Quality Reverse Injection Molding Factory – Ppr fitting mould nos of cavity customized – Yaxi Mould , The product will supply to all over the world, such as: Croatia, Turkmenistan, Grenada, Our company abides by the management idea of "keep innovation, pursue excellence". On the basis of assuring the advantages of existing products, we continuously strengthen and extend product development. Our company insists on innovation to promote the sustainable development of enterprise, and make us become the domestic high-quality suppliers.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.