OEM Cheap Plastic Injection Mold Components Factory – UPVC fitting mould Steel of Cavity & Core DIN 1.2316 – Yaxi Mould

OEM Cheap Plastic Injection Mold Components Factory – UPVC fitting mould Steel of Cavity & Core DIN 1.2316 – Yaxi Mould Detail:

v:* {behavior:url(#default#VML);}

o:* {behavior:url(#default#VML);}

x:* {behavior:url(#default#VML);}

.shape {behavior:url(#default#VML);}

| Model NO. | JZ-P-C-03-021-A | Warranty | 12 Months |

| Metal Color | Black Metal | Customized | Customized |

| Condition | New | Size | 100mm |

| Transport Package | Wooden Case | Specification | IS09001: 2000 |

| Trademark | JZ | Origin | China |

| HS Code | 8480719090 | Production Capacity | 100 Sets/Month |

Product Description

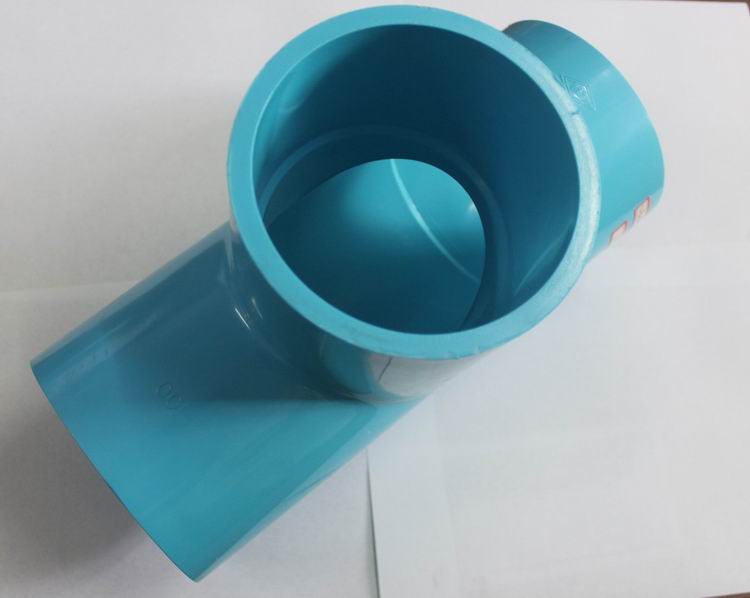

PVC Injection Collapsible Core Fitting Mould

High quality with reasonable price and short delivery time

| Name | PVC Injection Collapsible Core Fitting Mould |

| Plastic material | PVC |

| Steel of Cavity & Core | DIN 1.2316 |

| Steel of Mouldbase | S50C. LkM standard^ etc |

| Nos of Cavity | Customized |

| Hardness of Cavity & Core | 42-45HRC |

| Hardness of Wear Parts | 42-48HRC |

| Core pulling system | Motor /oil cylinder/ stripping plate, angel pin^ etc |

| Mould Accessories | DME/HASCO Standard A |

| Cooling system | In core baffle cooling and in cavity plate chain dilling type cooling |

| Surface fnish | Diamond polish |

| Molding life | 1,000, 000shots |

| Runner | Cold |

| Delivery time | 75 work days |

| Packing | wooden case |

| Payment | T/T L/C |

Serve

1. R& D We support customer R& D.

2. Quotation Making Mould Quotation will be finished in one day based on information given.

3. Negotiation The quality, price, material, delivery time, payment ect.

4. Mould Design 3-5 days for mould and product 3D drawing design

5. Mould Make moulds based on customers’ requirements. Mould design sent to customer for approval first.

Mould will be usually finished in 60 days

6. Mould Testing When moulds are finished, we will test the mould to check whether it meets customers’ needs.

And we will send samples for reference.

7. Sample If the first sample comes out do not satisfy customers, we will modify the mould until meeting

customers’ satisfaction.

8. Delivery Deliver by sea or by train for PPR pipe mould, according to customers’ requirement.

Product detail pictures:

Related Product Guide:

Cooperation

Normally customer-oriented, and it's our ultimate concentrate on for being not only one of the most dependable, trustable and honest supplier, but also the partner for our shoppers for OEM Cheap Plastic Injection Mold Components Factory – UPVC fitting mould Steel of Cavity & Core DIN 1.2316 – Yaxi Mould , The product will supply to all over the world, such as: Madagascar, Naples, Bogota, With the spirit of "credit first, development through innovation, sincere cooperation and joint growth", our company is striving to create a brilliant future with you, so as to become a most valuable platform for exporting our products in China!

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!